Accessories and spare parts

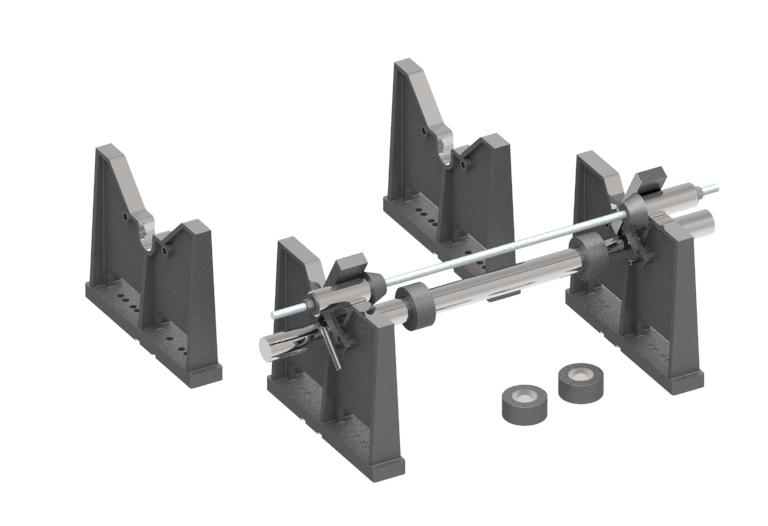

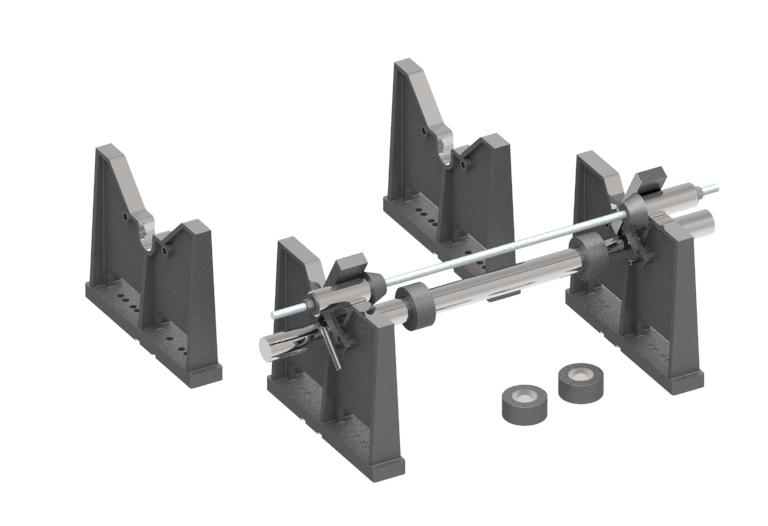

PV1516

PV1516 60° - 90° V-block blueprinting mounting fixture

PV0025

PV0025 Pair of fast clamping column

PV0007

PV0007 Pair of parallel supports H=49mm

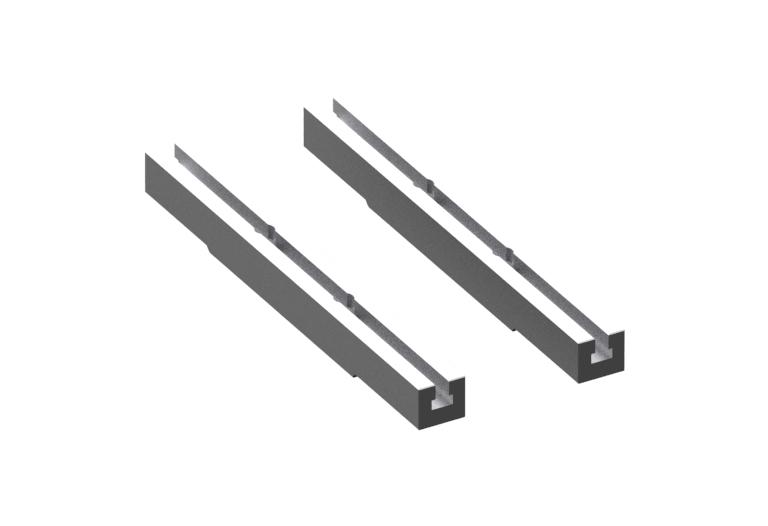

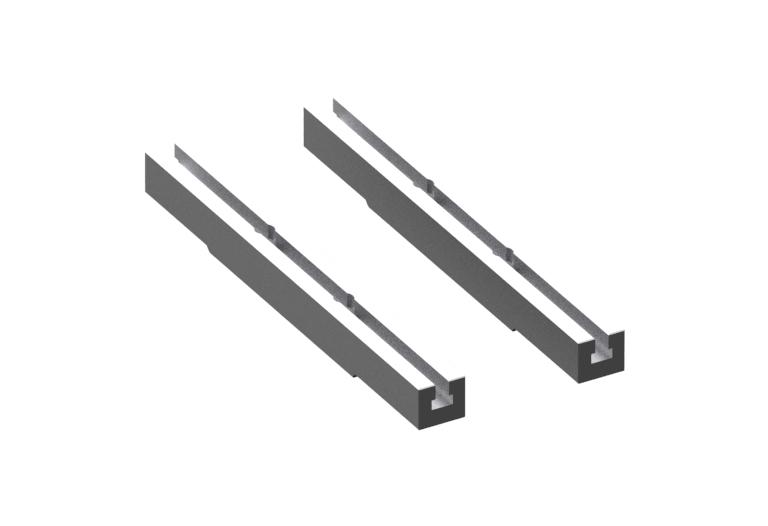

PV0160

PV0160 Pair of parallel supports

UT1320

3/8” CBN/PCD insert tool holder

UT1355

1/2” CBN Insert for cast iron

UT1356

1/2” PCD Insert for aluminium

B03560

Ø 35÷60 mm L = 330 mm boring kit with dial gauge adjustment

B06085

Ø 60÷85 mm L = 320 mm boring kit with dial gauge adjustment

C03560

Ø 35÷60 mm L = 330 mm boring kit with pre-setting system

C06085

Ø 60÷85 mm L = 320 mm boring kit with pre-setting system

C85170

Ø 85÷170 mm L= 360 mm boring kit with pre-setting system

B85170

Ø 85÷170 mm L = 360 mm boring kit dial gauge adjustment

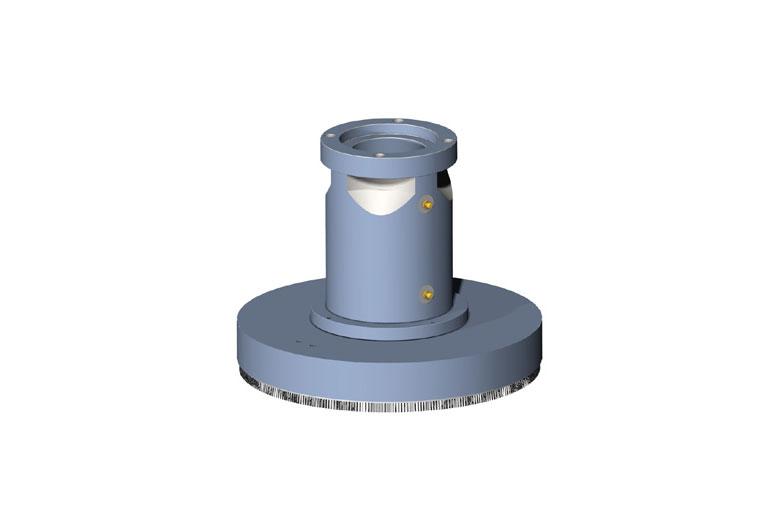

PF0350

1/2” CBN or PCD milling plate dia. 350 mm (available only for ACF)

UT1330

1/2”CBN/PCD insert tool holder

UT1345

3/8” CBN Insert for cast iron

UT1346

3/8” PCD Insert for aluminium

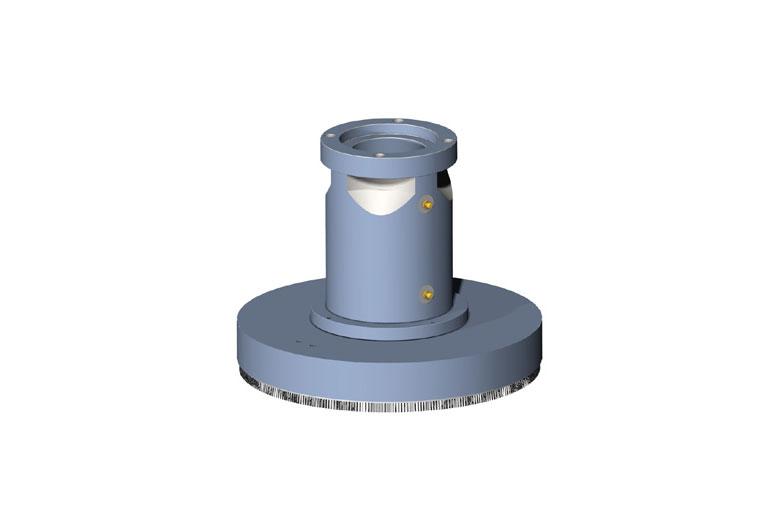

SSR200

Spindle storage rack

PVB015

V-block adjustable universal fixture

APC040

CAT40 taper spindle for drilling

ACF500

Tool sharpening assembly with support with diamond wheel ACF550