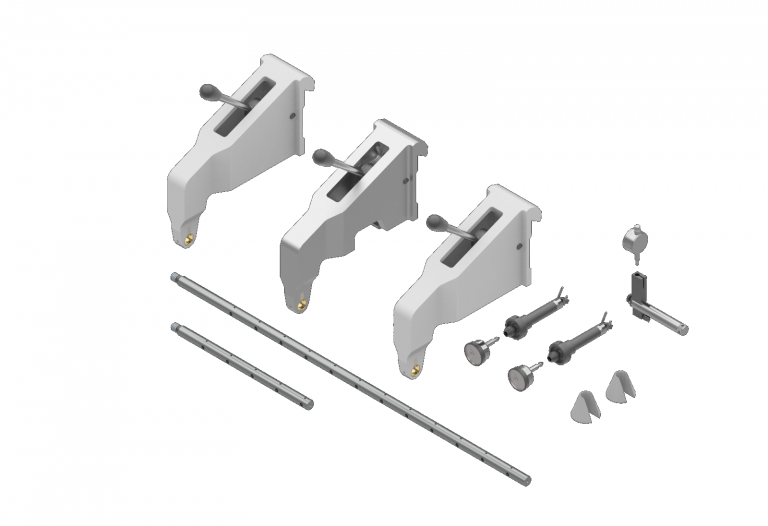

The Line Boring Machine LBM950 allows the reconditioning of housing holes either of camshaft cylinder heads and crankshaft blocks of cars and light trucks as well. The innovative chrome bar drive system combines the two boring feed and rotation movements and consists of a linear ball bearing unit that ensures smooth and precise movement and a belt actuator that provides controlled rotation of the bar tool holder. All the operations related to the bar such as the manual movements, the setting of the working parameters and the automatic cycles are managed by touch screen panel that, combined with an electronic handweel, makes the the use of the LBM950 extremely intuitive, simple and very productive. The boring bar is hold by three sturdy, movable arms which offer high rigidity while machining, whilst perfect and quick centering of the workpiece respect to the boring seats is allowed thanks to fine adjustment knobs, either in height and cross movements, assisted by a pair of centering devices complete of dial indicators. The versatile and useful fixture simplify and speed-up the clamping operation of any kind of cylinder heads and blocks.