Mainly designed for the reconditioning of

drums and discs of medium and large vehicles, the TR1000 is extremely practical and versatile, thanks to its technical features.

Its reliability is ensured by the

simplicity of construction and, at the same time, by the

high structural strength, guaranteed by the extensive use of cast iron for the main parts such as the base, the table and the shaft holder.

The convenient and intuitive position of the control panel allows total managing of the machine functions, while the variable speeds of axis rotation and tool advancement always ensure ideal working conditions and the best finishing results.

The wide range of accessories extends its field of use also to the reconditioning of discs and drums of light vehicles and cars, as well as clutch flywheels.

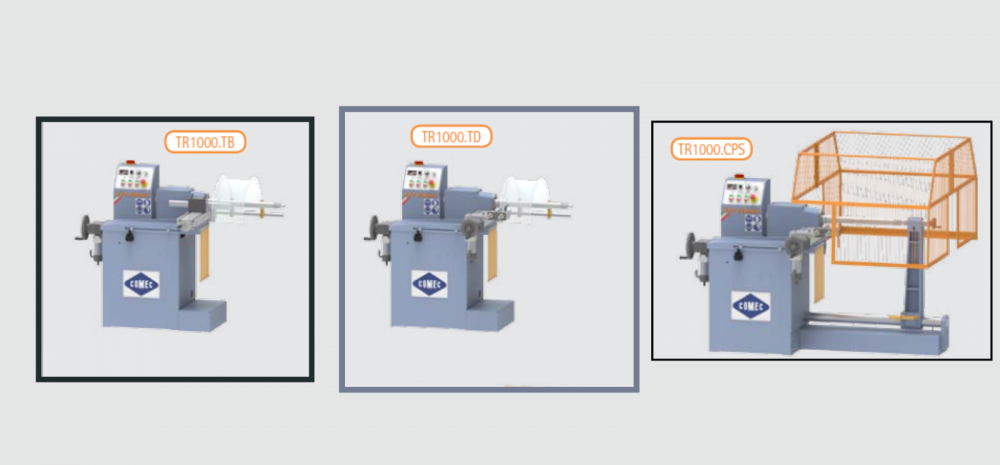

To meet different usage needs, the TR1000 is available in

3 different configurations:

This is the basic version, which allows you to work the drums of medium and heavy vehicles thanks to the standard equipment, which includes a 50 mm diameter cone holder shaft and a series of centering cones of different sizes.

The versatility of this machine also allows the reconditioning of drums of light vehicles and cars through the use of the optional TDL30 equipment, which includes a 30mm cone holder shaft and the relative spacers and centering cones.

- TR1000.TD - Brake disk and drum lathe

This version presents the same technical features of the TB model but, in addition, it includes the motorized cross slide and the double tool holder, which allow automatic turning of brake discs as well.

As for the TB version, the TDL30 accessory extends its use to light vehicles.

- TR1000.CPS - Brake disk and drum lathe with turning kit

This model is a refined reinterpretation of its predecessor, the

TR1500, from which we have extracted only the essentials to meet the needs of a wide range of users.

This certainly is the ideal solution when there is the need of reconditioning

industrial vehicle drums with twin wheels.

The elongated base and the shaft support ensure maximum stability and support for the axis on which the heavy weight of the drum-wheel assembly rests.

As for the previous versions, the machine is able to work any other type of drum or disc by using the optional accessories supplied on request.

For further information please visit:

https://www.comecpn.com/en/brakeclutch-line/tr1000-brake-disc-and-drum-lathe